At 3DNA, we are not just transforming eyewear, we redefine what manufacturing means in a digitally connected world. With our state-of-the-art smart factories, robotics automation, and commitment to sustainable practices, we’re solving the biggest pain points in the supply chain.

Billions in capital tied to physical stock. High costs: storage, depreciation, obsolescence. This core inefficiency represents ~90% of the problem 3DNA addresses.

Mould-dependent processes: slow, costly, high Minimum Order Quantities (MOQs). Extended lead times from geographically distant manufacturing hubs. Vulnerability to global trade disruptions and tariffs.

High production costs and slow lead times stifle innovation in eyewear design, making it difficult for brands to respond to shifting fashion trends, evolving consumer preferences.

The “Ouro” Smart Factory is built upon a foundation of proprietary and advanced digital manufacturing technologies.

Traditional reliance on expensive, time-consuming physical moulds. 3DNA Innovation: Digital control systems and advanced material processing eliminate the need for moulds, enabling direct manufacturing from digital files for any quantity.

Traditional reliance on expensive, time-consuming physical moulds. 3DNA Innovation: Digital control systems and advanced material processing eliminate the need for moulds, enabling direct manufacturing from digital files for any quantity.

Manual, labor-intensive, and error-prone generation of machine instructions. 3DNA Innovation: Our AI CAM Agent instantly translates 3D design data into optimized, error-free machine code at the point of order, accelerating production setup.

Manual, labor-intensive, and error-prone generation of machine instructions. 3DNA Innovation: Our AI CAM Agent instantly translates 3D design data into optimized, error-free machine code at the point of order, accelerating production setup.

Inefficient batch processing, high manual labor costs, production bottlenecks. 3DNA Innovation: A continuous-flow, ring-style manufacturing cell with integrated robotics for automated material handling and processing. Designed for modularity and local deployment.

Inefficient batch processing, high manual labor costs, production bottlenecks. 3DNA Innovation: A continuous-flow, ring-style manufacturing cell with integrated robotics for automated material handling and processing. Designed for modularity and local deployment.

Our revenue-generating solutions in retail technology and distributed manufacturing demonstrate market viability and form a foundational network for the “Ouro” Smart Factory.

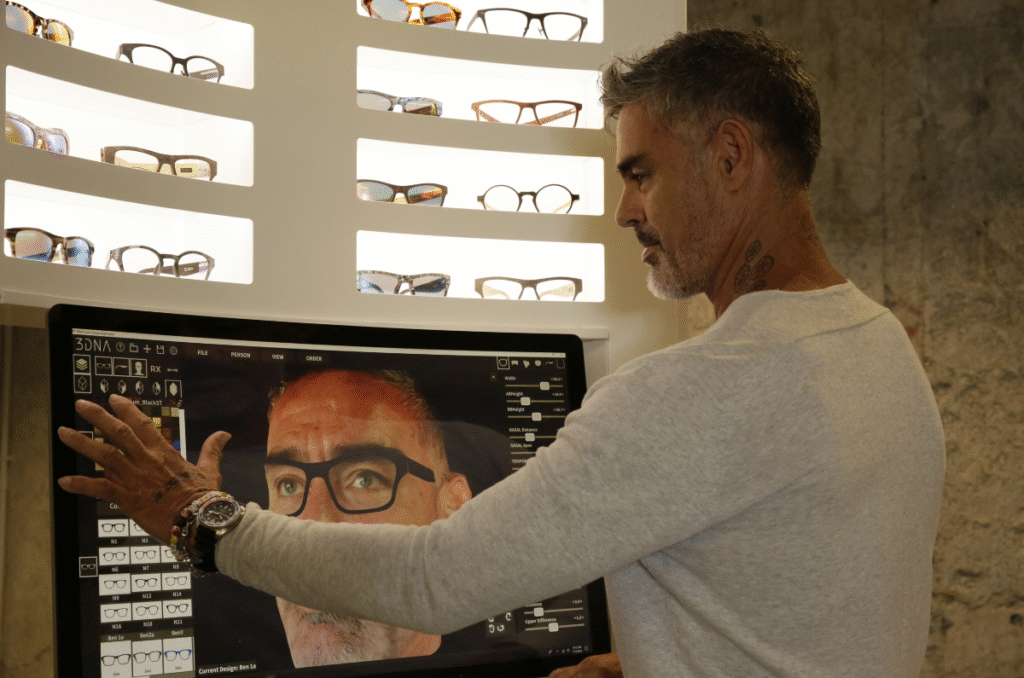

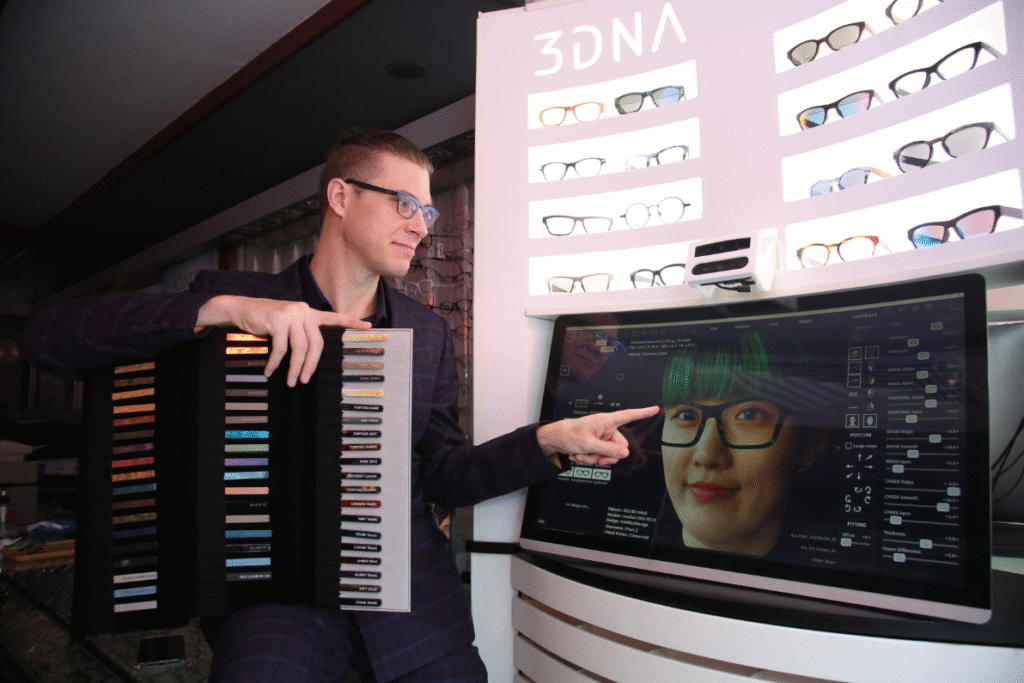

AI-assisted eyewear design applications, 3D facial scanning for automated biometric fitting, and interactive retail kiosks.

Relevance: These tools capture digital orders and design specifications that directly feed into the (future) Smart Factory production queue, demonstrating demand for digitally-native eyewear.

Current network of expert ateliers in 5 countries (US, India, France, UK, China) fulfilling bespoke and small-batch orders.

Relevance: Confirms the viability of localized, on-demand production and our white-label OEM service model. These ateliers provide the operational learning for scaling with “Ouro.”

A platform for eyewear brands (incumbent and emerging) to digitally design, manage, and distribute collections with minimal upfront inventory.

Relevance: Attracts B2B clients who are prime candidates for leveraging “Ouro’s” on-demand manufacturing capacity. Confirmed by growing inquiries and our backorder catalog.

3DNA’s digital manufacturing approach offers a significant competitive advantage for eyewear brands and manufacturers, addressing key market pressures.

Inventory Strategy

Mass Stockpiling (Just-in-Case)

On-Demand (Just-in-Time)

Capital Expenditure

High (Stock, Moulds, Warehousing)

Reduced (No Moulds, Less Stock)

Lead Times

Months

Days / Weeks

MOQ

High

None / Flexible

Supply Chain Risk

High (Global, Complex)

Localized, Agile

Design Agility

Slow, Expensive Iteration

Fast, Low-Cost Innovation

3DNA was co-founded by parametric design engineer Xiliu Yang and third-generation optician Dennis G. Zelazowski,

driven by a shared vision to revolutionize the eyewear industry.

At 3DNA, we are more than just an eyewear provider, we enable your brand to thrive with advanced manufacturing technology. Whether you’re a new brand looking to make your mark or an established business aiming to scale, our white-label OEM services offer the perfect solution to bring your vision to life.

We equip you with advanced technology, unmatched flexibility, and exceptional precision, ensuring that production concerns are no longer a barrier to your growth.

Showcasing our reliability and proven expertise in delivering quality solutions.

Crystal Vision “3DNA tech enables us to offer services our competitors can’t”

EGO Custom Eyewear “Our customers love the quality and personalization”

Drill Specialty Corp “3DNA helps us grow and innovate faster”

Explore our FAQs to learn how 3DNA creates custom eyewear tailored to your face, style, and vision needs

We excel in digital, on-demand manufacturing that redefines efficiency and customization for businesses. While eyewear is our specialty, we aim to empower brands to scale sustainably.

Of course! Our white-label solutions are designed to seamlessly integrate with your business, helping you grow without extra overhead.

By offering on-demand production, we eliminate excess inventory and reduce waste, so you save on storage, materials, and time.

For those who wear glasses, we bring a new level of personalization, where each pair is crafted to fit not only your face but your unique style. For those who sell them, we provide the tools to elevate your storefront and make every interaction seamless and unforgettable.

Visionaries looking to grow their brands can seamlessly scale production and push boundaries with our cutting-edge technology. And for those shaping the future of eyewear, our smart solutions streamline the process, delivering precision and efficiency in every frame.

We’re here to revolutionize the entire eyewear journey, making it better, smarter, and more exciting for everyone involved.

Explore how 3DNA’s advanced manufacturing solutions and the “Ouro” Smart Factory can optimize your supply chain,

reduce inventory costs, and accelerate your speed to market.

Copyright © 2025 All rights reserved 3DNA